Double Row Full Complement Cylindrical Roller Bearings

FV now offers a broader range of full complement cylindrical roller bearings to meet the need for increased radial load carrying capacity by maximizing the number of rollers in a given envelope. The expanded offering includes multiple series of one-row and two-row designs starting at 100 mm bore.

Design Attributes

Designed to ISO/DIN specified interchangeable boundary dimensions where available.

Sold as a completely unitized assembly.

Both single row and double row products available in same size range.

Standard designs use NCF, NNCF nomenclature.

Full complement construction, no cage included.

High capacity, but operating speed may be an issue requiring close application scrutiny.

Assembly outer ring design provides significant internal axial float capability.

|  |  |  |

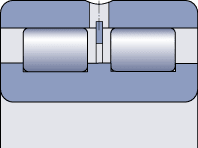

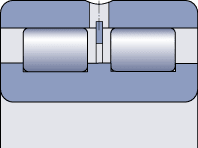

NNCL design |

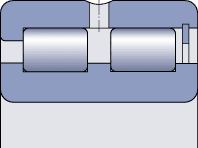

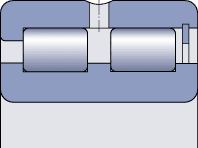

NNCF design |

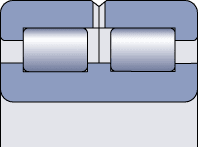

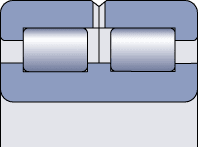

NNC design |

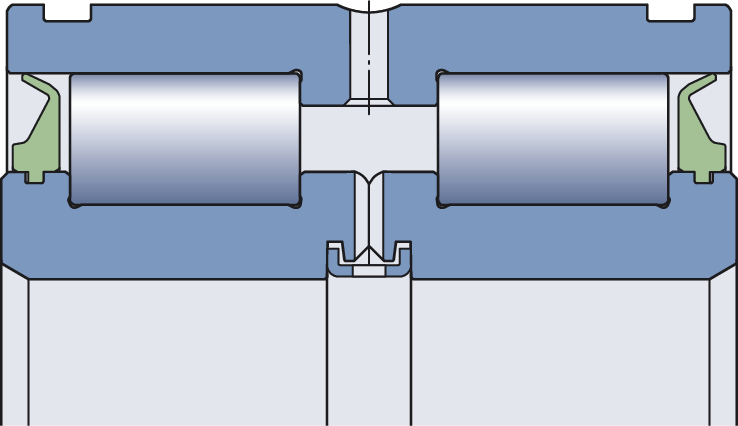

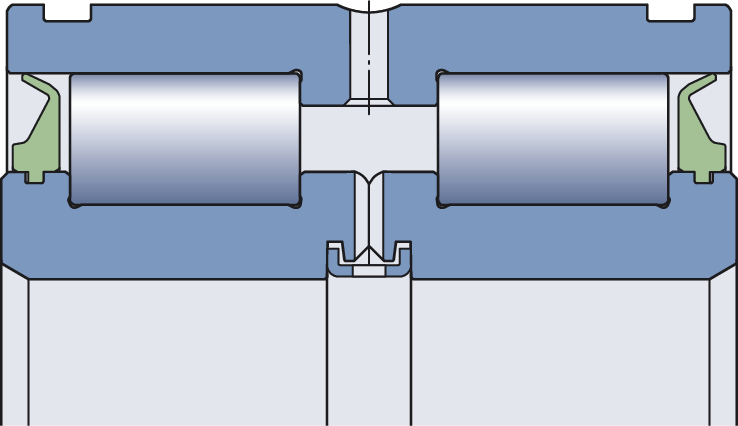

NNF (sealed design) |

Principal dimensions

[mm] | Basic load ratings [kN] | Fatigue load limit [kN] | Speed ratings | Designation |

| dynamic | static |

| Reference speed | Limiting speed |

|

| d | D | B | C | Co | Pu | [r/min] | [r/min] |

|

| 20 | 42 | 30 | 45.7 | 55 | 5.7 |

| 3400 | NNF 5004 ADB-2LSV |

| 20 | 42 | 30 | 52.3 | 57 | 6.2 | 8500 | 10000 | NNCF 5004 CV |

| 25 | 47 | 30 | 50.1 | 65.5 | 6.8 |

| 3000 | NNF 5005 ADB-2LSV |

| 25 | 47 | 30 | 59.4 | 71 | 7.65 | 7000 | 9000 | NNCF 5005 CV |

| 30 | 55 | 34 | 57.2 | 75 | 7.8 |

| 2600 | NNF 5006 ADB-2LSV |

| 30 | 55 | 34 | 73.7 | 88 | 10 | 6000 | 7500 | NNCF 5006 CV |

| 35 | 62 | 36 | 70.4 | 98 | 10.6 |

| 2200 | NNF 5007 ADB-2LSV |

| 35 | 62 | 36 | 89.7 | 112 | 12.9 | 5300 | 6700 | NNCF 5007 CV |

| 40 | 68 | 38 | 85.8 | 116 | 13.2 |

| 2000 | NNF 5008 ADB-2LSV |

| 40 | 68 | 38 | 106 | 140 | 17 | 4800 | 6000 | NNCF 5008 CV |

| 45 | 75 | 40 | 102 | 146 | 17 |

| 1800 | NNF 5009 ADB-2LSV |

| 45 | 75 | 40 | 112 | 156 | 18.3 | 4300 | 5300 | NNCF 5009 CV |

| 50 | 80 | 40 | 108 | 160 | 18.6 |

| 1700 | NNF 5010 ADB-2LSV |

| 50 | 80 | 40 | 142 | 196 | 23.6 | 4000 | 5000 | NNCF 5010 CV |

| 55 | 90 | 46 | 128 | 193 | 22.8 |

| 1500 | NNF 5011 ADB-2LSV |

| 55 | 90 | 46 | 190 | 280 | 34.5 | 3400 | 4300 | NNCF 5011 CV |

| 60 | 85 | 25 | 78.1 | 137 | 14.3 | 3600 | 4500 | NNC 4912 CV |

| 60 | 85 | 25 | 78.1 | 137 | 14.3 | 3600 | 4500 | NNCF 4912 CV |

| 60 | 85 | 25 | 78.1 | 137 | 14.3 | 3600 | 4500 | NNCL 4912 CV |

| 60 | 95 | 46 | 134 | 208 | 25 |

| 1400 | NNF 5012 ADB-2LSV |

| 60 | 95 | 46 | 198 | 300 | 36.5 | 3400 | 4000 | NNCF 5012 CV |

| 65 | 100 | 46 | 138 | 224 | 26.5 |

| 1300 | NNF 5013 ADB-2LSV |

| 65 | 100 | 46 | 209 | 325 | 40 | 3000 | 3800 | NNCF 5013 CV |

| 70 | 100 | 30 | 114 | 193 | 22.4 | 3000 | 3800 | NNC 4914 CV |

| 70 | 100 | 30 | 114 | 193 | 22.4 | 3000 | 3800 | NNCF 4914 CV |

| 70 | 100 | 30 | 114 | 193 | 22.4 | 3000 | 3800 | NNCL 4914 CV |

| 70 | 110 | 54 | 187 | 285 | 34.5 |

| 1200 | NNF 5014 ADB-2LSV |

| 70 | 110 | 54 | 238 | 345 | 45 | 2800 | 3600 | NNCF 5014 CV |

| 75 | 115 | 54 | 224 | 310 | 40 |

| 1100 | NNF 5015 ADB-2LSV |

| 75 | 115 | 54 | 251 | 380 | 49 | 2600 | 3200 | NNCF 5015 CV |

| 80 | 110 | 30 | 121 | 216 | 25 | 2600 | 3400 | NNC 4916 CV |

| 80 | 110 | 30 | 121 | 216 | 25 | 2600 | 3400 | NNCF 4916 CV |

| 80 | 110 | 30 | 121 | 216 | 25 | 2600 | 3400 | NNCL 4916 CV |

| 80 | 125 | 60 | 251 | 415 | 53 |

| 1000 | NNF 5016 B-2LS |

| 80 | 125 | 60 | 308 | 455 | 58.5 | 2400 | 3000 | NNCF 5016 CV |

| 85 | 130 | 60 | 270 | 430 | 55 |

| 1000 | NNF 5017 B-2LS |

| 85 | 130 | 60 | 314 | 475 | 60 | 2400 | 3000 | NNCF 5017 CV |

| 90 | 125 | 35 | 161 | 300 | 35.5 | 2400 | 3000 | NNC 4918 CV |

| 90 | 125 | 35 | 161 | 300 | 35.5 | 2400 | 3000 | NNCF 4918 CV |

| 90 | 125 | 35 | 161 | 300 | 35.5 | 2400 | 3000 | NNCL 4918 CV |

| 90 | 140 | 67 | 319 | 550 | 69.5 |

| 900 | NNF 5018 B-2LS |

| 90 | 140 | 67 | 369 | 560 | 69.5 | 2200 | 2800 | NNCF 5018 CV |

| 95 | 145 | 67 | 330 | 570 | 71 |

| 900 | NNF 5019 B-2LS |

| 100 | 140 | 40 | 209 | 400 | 46.5 | 2000 | 2600 | NNC 4920 CV |

| 100 | 140 | 40 | 209 | 400 | 46.5 | 2000 | 2600 | NNCF 4920 CV |

| 100 | 140 | 40 | 209 | 400 | 46.5 | 2000 | 2600 | NNCL 4920 CV |

| 100 | 150 | 67 | 336 | 570 | 68 |

| 850 | NNF 5020 B-2LS |

| 100 | 150 | 67 | 391 | 620 | 75 | 2000 | 2600 | NNCF 5020 CV |

| 110 | 150 | 40 | 220 | 430 | 49 | 1900 | 2400 | NNC 4922 CV |

| 110 | 150 | 40 | 220 | 430 | 49 | 1900 | 2400 | NNCF 4922 CV |

| 110 | 150 | 40 | 220 | 430 | 49 | 1900 | 2400 | NNCL 4922 CV |

| 110 | 170 | 80 | 413 | 695 | 81.5 |

| 750 | NNF 5022 B-2LS |

| 110 | 170 | 80 | 512 | 800 | 95 | 1800 | 2200 | NNCF 5022 CV |

| 120 | 165 | 45 | 242 | 480 | 53 | 1700 | 2200 | NNC 4924 CV |

| 120 | 165 | 45 | 242 | 480 | 53 | 1700 | 2200 | NNCF 4924 CV |

| 120 | 165 | 45 | 242 | 480 | 53 | 1700 | 2200 | NNCL 4924 CV |

| 120 | 180 | 80 | 429 | 750 | 86.5 |

| 700 | NNF 5024 B-2LS |

| 120 | 180 | 80 | 539 | 880 | 104 | 1700 | 2000 | NNCF 5024 CV |

| 130 | 180 | 50 | 297 | 530 | 60 | 1600 | 2000 | NNC 4926 CV |

| 130 | 180 | 50 | 297 | 530 | 60 | 1600 | 2000 | NNCF 4926 CV |

| 130 | 180 | 50 | 297 | 530 | 60 | 1600 | 2000 | NNCL 4926 CV |

| 130 | 190 | 80 | 446 | 815 | 91.5 |

| 670 | 319426 B-2LS |

| 130 | 200 | 95 | 616 | 1040 | 120 |

| 630 | NNF 5026 B-2LS |

| 130 | 200 | 95 | 765 | 1250 | 143 | 1500 | 1900 | NNCF 5026 CV |

| 140 | 190 | 50 | 308 | 570 | 63 | 1500 | 1900 | NNC 4928 CV |

| 140 | 190 | 50 | 308 | 570 | 63 | 1500 | 1900 | NNCF 4928 CV |

| 140 | 190 | 50 | 308 | 570 | 63 | 1500 | 1900 | NNCL 4928 CV |

| 140 | 200 | 80 | 468 | 865 | 96.5 |

| 630 | 319428 DA-2LS |

| 140 | 210 | 95 | 644 | 1120 | 127 |

| 600 | NNF 5028 B-2LS |

| 140 | 210 | 95 | 809 | 1370 | 153 | 1400 | 1800 | NNCF 5028 CV |

| 150 | 190 | 40 | 255 | 585 | 60 | 1500 | 1800 | NNC 4830 CV |

| 150 | 190 | 40 | 255 | 585 | 60 | 1500 | 1800 | NNCF 4830 CV |

| 150 | 190 | 40 | 255 | 585 | 60 | 1500 | 1800 | NNCL 4830 CV |

| 150 | 210 | 60 | 429 | 830 | 91.5 | 1400 | 1700 | NNC 4930 CV |

| 150 | 210 | 60 | 429 | 830 | 91.5 | 1400 | 1700 | NNCF 4930 CV |

| 150 | 210 | 60 | 429 | 830 | 91.5 | 1400 | 1700 | NNCL 4930 CV |

| 150 | 210 | 80 | 484 | 915 | 100 |

| 600 | 319430 B-2LS |

| 150 | 225 | 100 | 748 | 1290 | 143 |

| 560 | NNF 5030 B-2LS |

| 150 | 225 | 100 | 842 | 1430 | 160 | 1300 | 1700 | NNCF 5030 CV |

| 160 | 200 | 40 | 260 | 610 | 62 | 1400 | 1700 | NNC 4832 CV |

| 160 | 200 | 40 | 260 | 610 | 62 | 1400 | 1700 | NNCF 4832 CV |

| 160 | 200 | 40 | 260 | 610 | 62 | 1400 | 1700 | NNCL 4832 CV |

| 160 | 220 | 60 | 446 | 915 | 96.5 | 1300 | 1600 | NNC 4932 CV |

| 160 | 220 | 60 | 446 | 915 | 96.5 | 1300 | 1600 | NNCF 4932 CV |

| 160 | 220 | 60 | 446 | 915 | 96.5 | 1300 | 1600 | NNCL 4932 CV |

| 160 | 220 | 80 | 501 | 1000 | 106 |

| 530 | 319432 DA-2LS |

| 160 | 240 | 109 | 781 | 1400 | 153 |

| 500 | NNF 5032 B-2LS |

| 160 | 240 | 109 | 952 | 1600 | 180 | 1200 | 1500 | NNCF 5032 CV |

| 170 | 215 | 45 | 286 | 655 | 65.5 | 1300 | 1600 | NNC 4834 CV |

| 170 | 215 | 45 | 286 | 655 | 65.5 | 1300 | 1600 | NNCF 4834 CV |

| 170 | 215 | 45 | 286 | 655 | 65.5 | 1300 | 1600 | NNCL 4834 CV |

| 170 | 230 | 60 | 457 | 950 | 100 | 1200 | 1500 | NNC 4934 CV |

| 170 | 230 | 60 | 457 | 950 | 100 | 1200 | 1500 | NNCF 4934 CV |

| 170 | 230 | 60 | 457 | 950 | 100 | 1200 | 1500 | NNCL 4934 CV |

| 170 | 230 | 80 | 512 | 1060 | 110 |

| 530 | 319434 B-2LS |

| 170 | 260 | 122 | 1010 | 1800 | 193 |

| 480 | NNF 5034 B-2LS |

| 170 | 260 | 122 | 1230 | 2120 | 236 | 1100 | 1400 | NNCF 5034 CV |

| 180 | 225 | 45 | 297 | 695 | 69.5 | 1200 | 1500 | NNC 4836 CV |

| 180 | 225 | 45 | 297 | 695 | 69.5 | 1200 | 1500 | NNCF 4836 CV |

| 180 | 225 | 45 | 297 | 695 | 69.5 | 1200 | 1500 | NNCL 4836 CV |

| 180 | 240 | 80 | 528 | 1100 | 114 |

| 480 | 319436 DA-2LS |

| 180 | 250 | 69 | 594 | 1220 | 127 | 1100 | 1400 | NNC 4936 CV |

| 180 | 250 | 69 | 594 | 1220 | 127 | 1100 | 1400 | NNCF 4936 CV |

| 180 | 250 | 69 | 594 | 1220 | 127 | 1100 | 1400 | NNCL 4936 CV |

| 180 | 280 | 136 | 1170 | 2120 | 228 |

| 450 | NNF 5036 B-2LS |

| 180 | 280 | 136 | 1420 | 2500 | 270 | 1100 | 1300 | NNCF 5036 CV |

| 190 | 240 | 50 | 358 | 750 | 76.5 | 1100 | 1400 | NNC 4838 CV |

| 190 | 240 | 50 | 358 | 750 | 76.5 | 1100 | 1400 | NNCF 4838 CV |

| 190 | 240 | 50 | 358 | 750 | 76.5 | 1100 | 1400 | NNCL 4838 CV |

| 190 | 260 | 69 | 605 | 1290 | 132 | 1100 | 1400 | NNC 4938 CV |

| 190 | 260 | 69 | 605 | 1290 | 132 | 1100 | 1400 | NNCF 4938 CV |

| 190 | 260 | 69 | 605 | 1290 | 132 | 1100 | 1400 | NNCL 4938 CV |

| 190 | 260 | 80 | 550 | 1180 | 120 |

| 450 | 319438 DA-2LS |

| 190 | 290 | 136 | 1190 | 2200 | 236 |

| 430 | NNF 5038 B-2LS |

| 190 | 290 | 136 | 1470 | 2600 | 280 | 1000 | 1300 | NNCF 5038 CV |

| 200 | 250 | 50 | 369 | 800 | 80 | 1100 | 1400 | NNC 4840 CV |

| 200 | 250 | 50 | 369 | 800 | 80 | 1100 | 1400 | NNCF 4840 CV |

| 200 | 250 | 50 | 369 | 800 | 80 | 1100 | 1400 | NNCL 4840 CV |

| 200 | 270 | 80 | 627 | 1370 | 137 | 950 | 1300 | 319440 B-2LS |

| 200 | 280 | 80 | 704 | 1500 | 153 | 1000 | 1300 | NNC 4940 CV |

| 200 | 280 | 80 | 704 | 1500 | 153 | 1000 | 1300 | NNCF 4940 CV |

| 200 | 280 | 80 | 704 | 1500 | 153 | 1000 | 1300 | NNCL 4940 CV |

| 200 | 310 | 150 | 1450 | 2900 | 300 |

| 400 | NNF 5040 B-2LS |

| 200 | 310 | 150 | 1680 | 3050 | 320 | 950 | 1200 | NNCF 5040 CV |

| 220 | 270 | 50 | 352 | 865 | 85 | 1000 | 1200 | NNC 4844 CV |

| 220 | 270 | 50 | 380 | 865 | 85 | 1000 | 1200 | NNCF 4844 CV |

| 220 | 270 | 50 | 380 | 865 | 85 | 1000 | 1200 | NNCL 4844 CV |

| 220 | 300 | 80 | 737 | 1600 | 160 | 950 | 1200 | NNC 4944 CV |

| 220 | 300 | 80 | 737 | 1600 | 160 | 950 | 1200 | NNCF 4944 CV |

| 220 | 300 | 80 | 737 | 1600 | 160 | 950 | 1200 | NNCL 4944 CV |

| 220 | 300 | 95 | 880 | 1860 | 190 |

| 380 | 319444 B-2LS |

| 220 | 340 | 160 | 1610 | 3100 | 315 |

| 360 | NNF 5044 B-2LS |

| 220 | 340 | 160 | 2010 | 3600 | 375 | 850 | 1100 | NNCF 5044 CV |

| 240 | 300 | 60 | 539 | 1290 | 125 | 900 | 1100 | NNC 4848 CV |

| 240 | 300 | 60 | 539 | 1290 | 125 | 900 | 1100 | NNCF 4848 CV |

| 240 | 300 | 60 | 539 | 1290 | 125 | 900 | 1100 | NNCL 4848 CV |

| 240 | 320 | 80 | 781 | 1760 | 173 | 850 | 1100 | NNC 4948 CV |

| 240 | 320 | 80 | 781 | 1760 | 173 | 850 | 1100 | NNCF 4948 CV |

| 240 | 320 | 80 | 781 | 1760 | 173 | 850 | 1100 | NNCL 4948 CV |

| 240 | 320 | 95 | 952 | 2040 | 200 |

| 360 | 319448 B-2LS |

| 240 | 360 | 160 | 1680 | 3350 | 335 |

| 340 | NNF 5048 B-2LS |

| 240 | 360 | 160 | 2120 | 3900 | 400 | 800 | 1000 | NNCF 5048 CV |

| 260 | 320 | 60 | 561 | 1400 | 132 | 800 | 1000 | NNC 4852 CV |

| 260 | 320 | 60 | 561 | 1400 | 132 | 800 | 1000 | NNCF 4852 CV |

| 260 | 320 | 60 | 561 | 1400 | 132 | 800 | 1000 | NNCL 4852 CV |

| 260 | 340 | 95 | 990 | 2160 | 212 |

| 340 | 319452 B-2LS |

| 260 | 360 | 100 | 1170 | 2550 | 245 | 750 | 950 | NNCF 4952 CV |

| 260 | 360 | 100 | 1170 | 2550 | 245 | 750 | 950 | NNCL 4952 CV |

| 260 | 400 | 190 | 2420 | 4650 | 455 |

| 300 | NNF 5052 B-2LS |

| 260 | 400 | 190 | 2860 | 5100 | 500 | 700 | 900 | NNCF 5052 CV |

| 280 | 350 | 69 | 737 | 1860 | 173 | 750 | 950 | NNC 4856 CV |

| 280 | 350 | 69 | 737 | 1860 | 173 | 750 | 950 | NNCF 4856 CV |

| 280 | 350 | 69 | 737 | 1860 | 173 | 750 | 950 | NNCL 4856 CV |

| 280 | 380 | 100 | 1210 | 2700 | 255 | 700 | 900 | NNCF 4956 CV |

| 280 | 380 | 100 | 1210 | 2700 | 255 | 700 | 900 | NNCL 4956 CV |

| 280 | 420 | 190 | 2550 | 5000 | 490 |

| 280 | NNF 5056 B-2LS |

| 280 | 420 | 190 | 2920 | 5300 | 520 | 670 | 850 | NNCF 5056 CV |

| 300 | 380 | 80 | 858 | 2120 | 196 | 700 | 850 | NNC 4860 CV |

| 300 | 380 | 80 | 858 | 2120 | 196 | 700 | 850 | NNCF 4860 CV |

| 300 | 380 | 80 | 858 | 2120 | 196 | 700 | 850 | NNCL 4860 CV |

| 300 | 420 | 118 | 1680 | 3750 | 355 | 670 | 800 | NNC 4960 CV |

| 300 | 420 | 118 | 1680 | 3750 | 355 | 670 | 800 | NNCF 4960 CV |

| 300 | 420 | 118 | 1680 | 3750 | 355 | 670 | 800 | NNCL 4960 CV |

| 300 | 460 | 218 | 3520 | 6550 | 600 | 600 | 750 | NNCF 5060 CV |

| 320 | 400 | 80 | 897 | 2280 | 208 | 630 | 800 | NNC 4864 CV |

| 320 | 400 | 80 | 897 | 2280 | 208 | 630 | 800 | NNCF 4864 CV |

| 320 | 400 | 80 | 897 | 2280 | 208 | 630 | 800 | NNCL 4864 CV |

| 320 | 440 | 118 | 1760 | 4050 | 375 | 600 | 750 | NNCF 4964 CV |

| 320 | 440 | 118 | 1760 | 4050 | 375 | 600 | 750 | NNCL 4964 CV |

| 320 | 480 | 218 | 3690 | 6950 | 620 | 560 | 700 | NNCF 5064 CV |

| 340 | 420 | 80 | 913 | 2400 | 216 | 600 | 750 | NNC 4868 CV |

| 340 | 420 | 80 | 913 | 2400 | 216 | 600 | 750 | NNCF 4868 CV |

| 340 | 420 | 80 | 913 | 2400 | 216 | 600 | 750 | NNCL 4868 CV |

| 340 | 460 | 118 | 1790 | 4250 | 390 | 560 | 700 | NNCF 4968 CV |

| 340 | 460 | 118 | 1790 | 4250 | 390 | 560 | 700 | NNCL 4968 CV |

| 340 | 520 | 243 | 4400 | 8300 | 710 | 530 | 670 | NNCF 5068 CV |

| 360 | 440 | 80 | 935 | 2550 | 224 | 560 | 700 | NNCF 4872 CV |

| 360 | 440 | 80 | 935 | 2550 | 224 | 560 | 700 | NNCL 4872 CV |

| 360 | 480 | 118 | 1830 | 4500 | 405 | 530 | 670 | NNCF 4972 CV |

| 360 | 480 | 118 | 1830 | 4500 | 405 | 530 | 670 | NNCL 4972 CV |

| 360 | 540 | 243 | 4180 | 8650 | 735 | 500 | 630 | NNCF 5072 CV |

| 380 | 480 | 100 | 1400 | 3650 | 315 | 530 | 670 | NNCF 4876 CV |

| 380 | 480 | 100 | 1400 | 3650 | 315 | 530 | 670 | NNCL 4876 CV |

| 380 | 520 | 140 | 2380 | 5700 | 500 | 500 | 630 | NNCF 4976 CV |

| 380 | 520 | 140 | 2380 | 5700 | 500 | 500 | 630 | NNCL 4976 CV |

| 380 | 560 | 243 | 4680 | 9150 | 750 | 480 | 600 | NNCF 5076 CV |

| 400 | 500 | 100 | 1420 | 3750 | 325 | 500 | 630 | NNCF 4880 CV |

| 400 | 500 | 100 | 1420 | 3750 | 325 | 500 | 630 | NNCL 4880 CV |

| 400 | 540 | 140 | 2420 | 6000 | 520 | 480 | 600 | NNCF 4980 CV |

| 400 | 540 | 140 | 2420 | 6000 | 520 | 480 | 600 | NNCL 4980 CV |

| 400 | 600 | 272 | 5500 | 11000 | 900 | 450 | 560 | NNCF 5080 CV

|

Cylindrical roller bearings are available in a wide range of designs, series, variants and sizes. The main design differences are the number of roller rows and the inner/outer ring flanges as well as cage designs and materials.

The bearings can meet the challenges of applications faced with heavy radial loads and high speeds. Accommodating axial displacement (except for bearings with flanges on both the inner and outer rings), they offer high stiffness, low friction and long service life.

Cylindrical roller bearings are also available in sealed or split designs. In sealed bearings, the rollers are protected from contaminants, water and dust, while providing lubricant retention and contaminant exclusion. This provides lower friction and longer service life. Split bearings are intended primarily for bearing arrangements which are difficult to access, such as crank shafts, where they simplify maintenance and replacements.

Special variants

In addition to the bearings presented in this section, FV supplies cylindrical roller bearings for special application requirements. This assortment includes:

Features and benefits:

High load carrying capacity

High stiffness

Accommodate axial displacement

Low friction

Long service life

Enhanced operational reliability

Separable and interchangeable

Cylindrical roller bearings are available in a wide range of designs, series, variants and sizes. The main design differences are the number of roller rows and the inner/outer ring flanges as well as cage designs and materials.

The bearings can meet the challenges of applications faced with heavy radial loads and high speeds. Accommodating axial displacement (except for bearings with flanges on both the inner and outer rings), they offer high stiffness, low friction and long service life.

Cylindrical roller bearings are also available in sealed or split designs. In sealed bearings, the rollers are protected from contaminants, water and dust, while providing lubricant retention and contaminant exclusion. This provides lower friction and longer service life. Split bearings are intended primarily for bearing arrangements which are difficult to access, such as crank shafts, where they simplify maintenance and replacements.

Special variants

In addition to the bearings presented in this section, FV supplies cylindrical roller bearings for special application requirements. This assortment includes:

Features and benefits:

High load carrying capacity

High stiffness

Accommodate axial displacement

Low friction

Long service life

Enhanced operational reliability

Separable and interchangeable

Cylindrical roller bearings are available in a wide range of designs, series, variants and sizes. The main design differences are the number of roller rows and the inner/outer ring flanges as well as cage designs and materials.

The bearings can meet the challenges of applications faced with heavy radial loads and high speeds. Accommodating axial displacement (except for bearings with flanges on both the inner and outer rings), they offer high stiffness, low friction and long service life.

Cylindrical roller bearings are also available in sealed or split designs. In sealed bearings, the rollers are protected from contaminants, water and dust, while providing lubricant retention and contaminant exclusion. This provides lower friction and longer service life. Split bearings are intended primarily for bearing arrangements which are difficult to access, such as crank shafts, where they simplify maintenance and replacements.

Special variants

In addition to the bearings presented in this section, FV supplies cylindrical roller bearings for special application requirements. This assortment includes:

Features and benefits:

High load carrying capacity

High stiffness

Accommodate axial displacement

Low friction

Long service life

Enhanced operational reliability

Separable and interchangeable