| No. | Bearing design | Ring and flange design | Cage design |

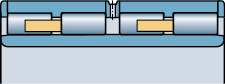

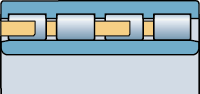

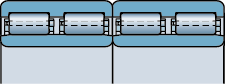

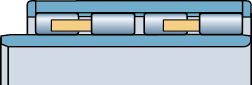

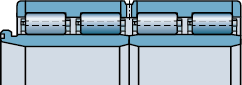

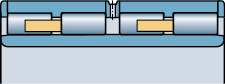

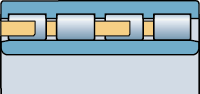

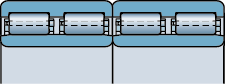

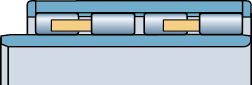

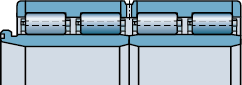

| BC4.1 design |

| two outer rings

each with three integral flanges

one inner ring

no flanges | two cages

machined brass or steel

double prong-type

roller centred |

| BC4T.1 design |

| two outer rings

each with three integral flanges

one inner ring

tapered bore

no flanges | two cages

machined brass or steel

double prong-type

roller centred |

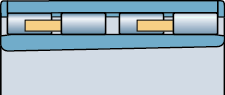

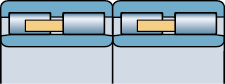

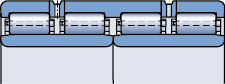

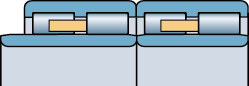

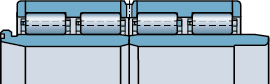

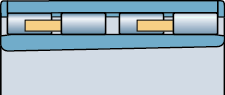

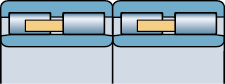

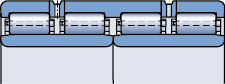

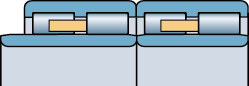

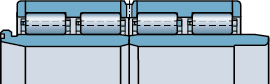

| BC4.2 design |

| two outer rings

each with three integral flanges

intermediate ring in between

one inner ring

no flanges | two cages

machined brass or steel

double prong-type

roller centred |

| BC4T.2 design |  | two outer rings

each with three integral flanges

intermediate ring in between

one inner ring

tapered bore

no flanges | two cages

machined brass or steel

double prong-type

roller centred |

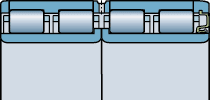

| BC4.3 design |  | two outer rings

each with an integral central flange

intermediate ring in between

two flange rings

one inner ring

no flanges | two cages

machined brass or steel

double prong-type

roller centred |

| BC4T.3 design |  | two outer rings

each with an integral central flange

intermediate ring in between

two flange rings

one inner ring

tapered bore

no flanges | two cages

machined brass or steel

double prong-type

roller centred |

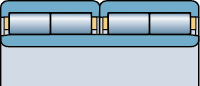

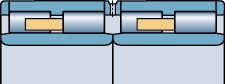

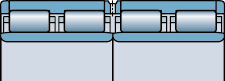

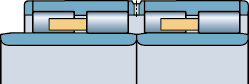

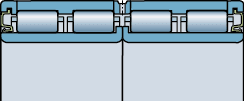

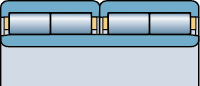

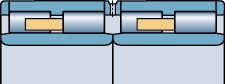

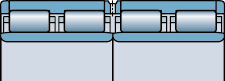

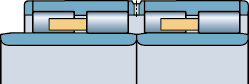

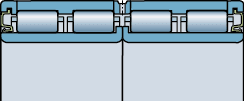

| BC4.4 design |

| two outer rings

each with two integral flanges

one inner ring

no flanges | two cages

machined brass

window-type

roller centred |

| BC4T.4 design |  | one outer ring

two flange rings

three guide rings

one inner ring

tapered bore

no flanges | two cages

machined brass or steel

double prong-type

roller centred |

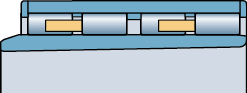

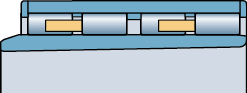

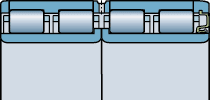

| BC4.5 design |

| one outer ring

two flange rings

three guide rings

one inner ring

no flanges | two cages

machined brass or steel

double prong-type

roller centred |

| BC4T.5 design |

| two outer rings

each with two integral flanges

two inner rings

no flanges | four cages

machined steel

pin-type

pierced rollers |

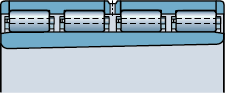

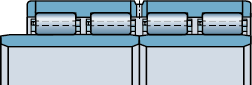

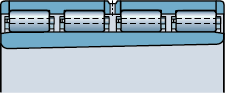

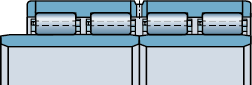

| BC4.6 design |

| two outer rings

each with an integral central flange

intermediate ring in between

two flange rings

four inner rings

no flanges | four cages

machined brass or steel

prong-type

roller centred |

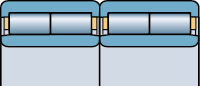

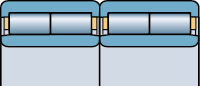

| BC4T.6 design |

| two outer rings

no flanges

two inner rings

each with three integral flanges | four cages

machined steel

pin-type

pierced rollers |

| BC4.7 design |  | one outer ring

two flange rings

three guide rings

one inner ring

extended on one side

no flanges | two cages

machined brass or steel

double prong-type

roller centred |

| BC4T.7 design |

| two outer rings

each with three integral flanges

two inner rings

one ring extended on one side

no flanges | two cages

machined brass or steel

double prong-type

roller centred |

| BC4.8 design |  | two outer rings

each with an integral central flange

intermediate ring in between

two flange rings

two inner rings

one ring extended on one side

no flanges | two cages

machined brass or steel

double prong-type

roller centred |

| BC4T.8 design |  | one outer ring

two flange rings

three guide rings

one inner ring

tapered bore

extended on one side with a lead-in taper

no flanges | two cages

machined brass or steel

double prong-type

roller centred |

| BC4.9 design |

| two outer rings

each with three integral flanges

two inner rings

no flanges | four cages

machined steel

pin-type

pierced rollers |

| BC4.10 design |  | two outer rings

each with an integral central flange

intermediate ring in between

two flange rings

two inner rings

no flanges | four cages

machined steel

pin-type

pierced rollers |

| BC4.11 design |  | two single row and one double row outer rings

two intermediate rings in between

each single row ring with an integral flange

double row ring with an integral central flange

two inner rings

no flanges | four cages

machined steel

pin-type

pierced rollers |

| BC4.12 design |  | two outer rings

each with an integral central flange

intermediate ring in between

two flange rings

two inner rings

no flanges | four cages

stamped steel

window-type

roller centred |

| BC4.13 design |  | two outer rings

each with two integral flanges

two inner rings

no flanges | two cages

machined brass

window-type

roller centred |

| BC4.14 design |  | two outer rings

each with an integral central flange

intermediate ring in between

two flange rings

four inner rings

no flanges | four cages

machined steel

pin-type

pierced rollers |

| BC4.15 design |  | two outer rings

no flanges

two inner rings

each with three integral flanges | four cages

machined steel

pin-type

pierced rollers |

| BC4.16 design |  | one outer ring

two flange rings

three guide rings

one inner ring

extended on one side

no flanges | two cages

machined brass or steel

double prong-type

roller centred |

| BC4.17 design |  | two outer rings

each with three integral flanges

two inner rings

one ring extended on one side

no flanges | two cages

machined brass or steel

double prong-type

roller centred |

| BC4.18 design |  | two outer rings

each with an integral central flange

intermediate ring in between

two flange rings

two inner rings

one ring extended on one side

no flanges | two cages

machined brass or steel

double prong-type

roller centred |

| BC4.19 design |  | two outer rings

each with an integral central flange

intermediate ring in between

two flange rings

two inner rings

one ring extended on one side

no flanges | four cages

machined steel

pin-type

pierced rollers |

| BC4.20 design |  | two outer rings

each with an integral central flange

intermediate ring in between

two flange rings

two inner rings

one ring extended on one side with a concentric shoulder

no flanges | four cages

machined steel

pin-type

pierced rollers |

| BC4.21 design |  | two outer rings

each with an integral central flange

intermediate ring in between

two flange rings

two inner rings

each extended on one side

one ring with a concentric shoulder

one ring with a lead-in taper

no flanges | four cages

machined steel

pin-type

pierced rollers |

BC4.22 design ( Seald type ) |  | two outer rings

each with an integral central flange intermediate ring in between two flange rings two inner ringseach with an integral flange | four cages stamped steel

window-type roller centred |

BC4.23 design ( Seald type ) |  | two outer rings each with an integral central flange intermediate ring in between two flange rings two inner ringseach with an integral flange | four cages stamped steel

window-type roller centred |