Applications: Conveyors, Marine propulsion systems, Fans and blowers, Cooling beds, Continuous casters, Stacker reclaimers, Plus many other applications

Cylindrical roller bearings are available in a wide range of designs, series, variants and sizes. The main design differences are the number of roller rows and the inner/outer ring flanges as well as cage designs and materials.

The bearings can meet the challenges of applications faced with heavy radial loads and high speeds. Accommodating axial displacement (except for bearings with flanges on both the inner and outer rings), they offer high stiffness, low friction and long service life.

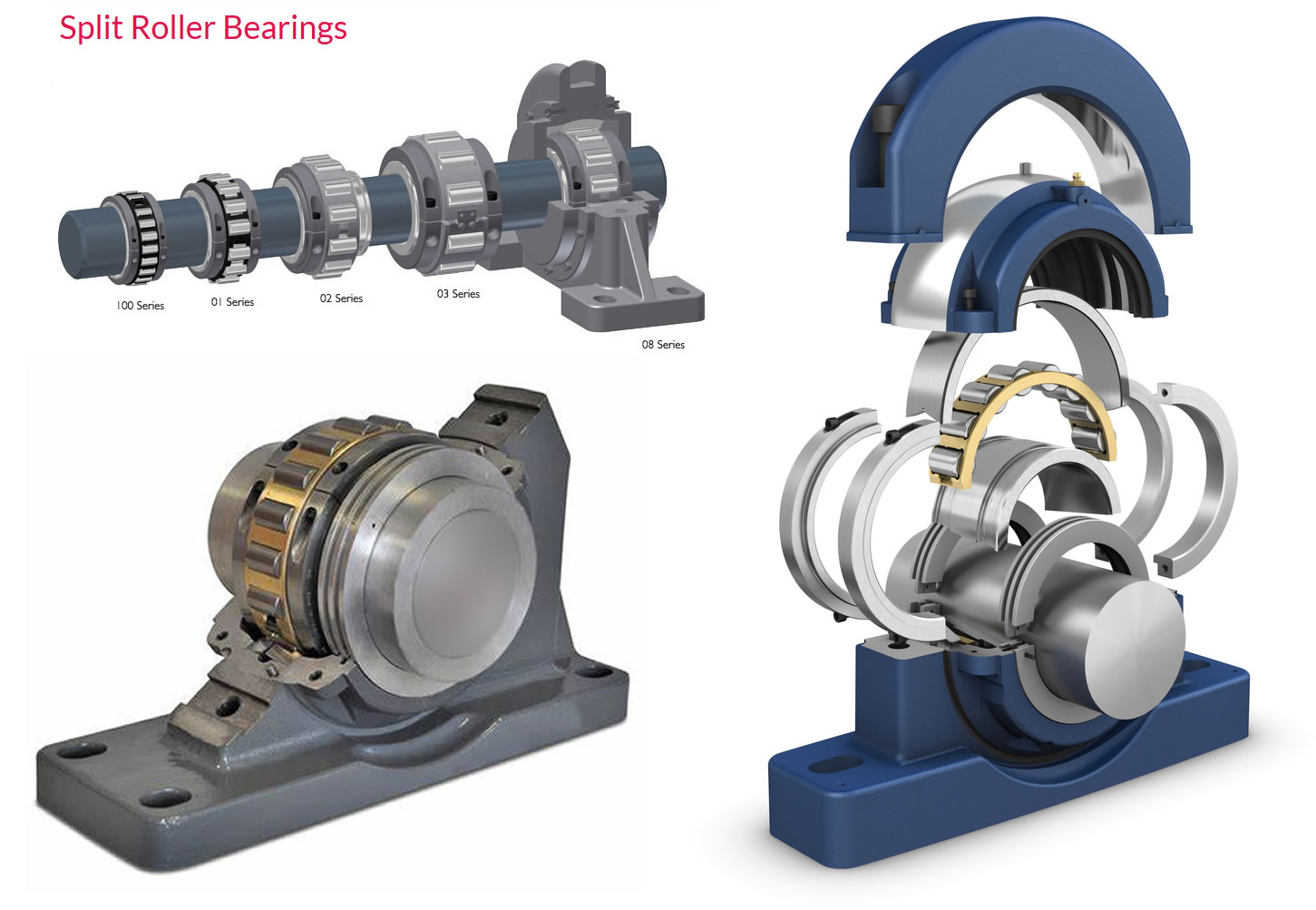

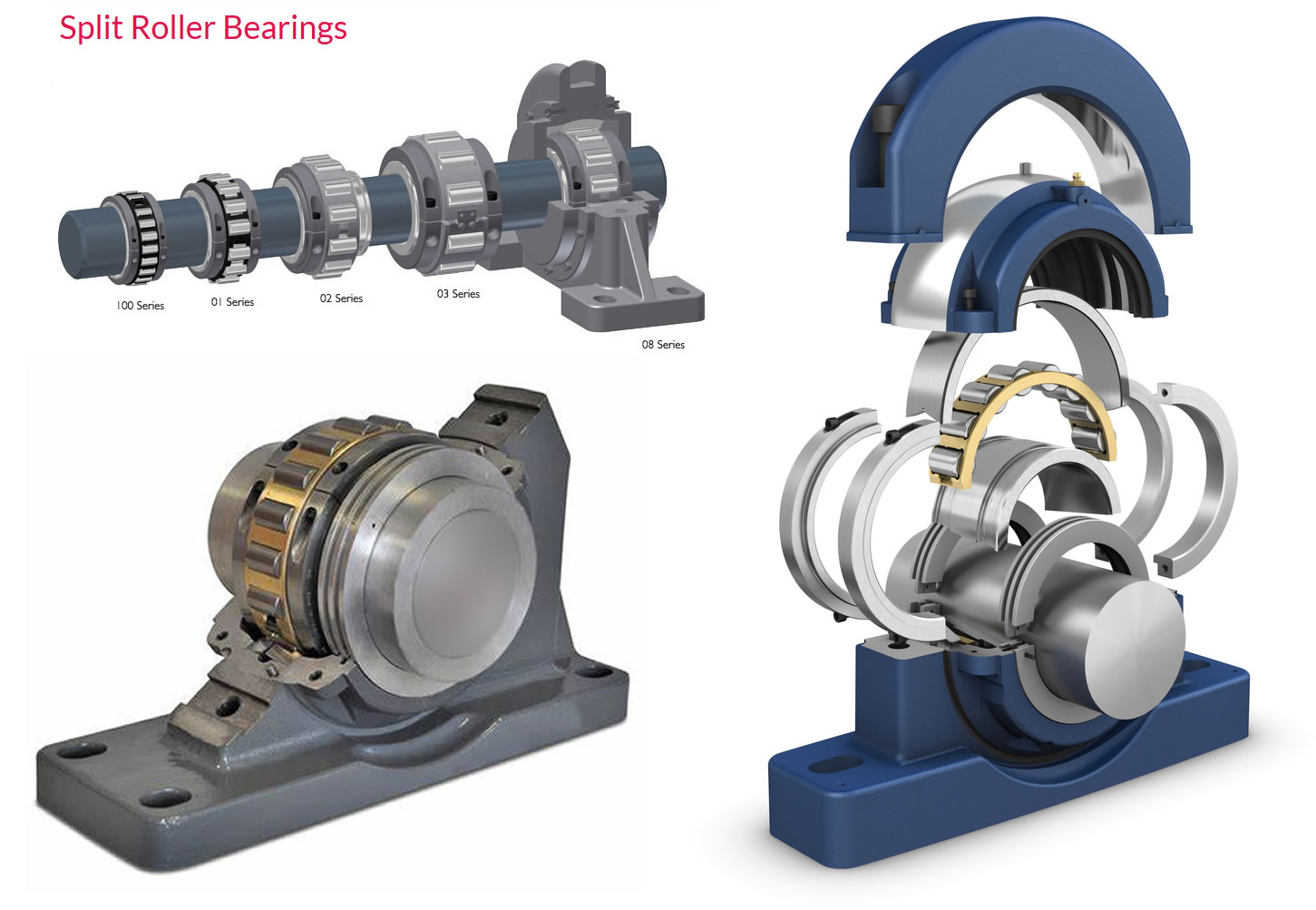

Cylindrical roller bearings are also available in sealed or split designs. In sealed bearings, the rollers are protected from contaminants, water and dust, while providing lubricant retention and contaminant exclusion. This provides lower friction and longer service life. Split bearings are intended primarily for bearing arrangements which are difficult to access, such as crank shafts, where they simplify maintenance and replacements.

Special variants

In addition to the bearings presented in this section, FV supplies cylindrical roller bearings for special application requirements. This assortment includes:

Features and benefits:

High load carrying capacity

High stiffness

Accommodate axial displacement

Low friction

Long service life

Enhanced operational reliability

Separable and interchangeable

Cylindrical roller bearings are available in a wide range of designs, series, variants and sizes. The main design differences are the number of roller rows and the inner/outer ring flanges as well as cage designs and materials.

The bearings can meet the challenges of applications faced with heavy radial loads and high speeds. Accommodating axial displacement (except for bearings with flanges on both the inner and outer rings), they offer high stiffness, low friction and long service life.

Cylindrical roller bearings are also available in sealed or split designs. In sealed bearings, the rollers are protected from contaminants, water and dust, while providing lubricant retention and contaminant exclusion. This provides lower friction and longer service life. Split bearings are intended primarily for bearing arrangements which are difficult to access, such as crank shafts, where they simplify maintenance and replacements.

Special variants

In addition to the bearings presented in this section, FV supplies cylindrical roller bearings for special application requirements. This assortment includes:

Features and benefits:

High load carrying capacity

High stiffness

Accommodate axial displacement

Low friction

Long service life

Enhanced operational reliability

Separable and interchangeable

Cylindrical roller bearings are available in a wide range of designs, series, variants and sizes. The main design differences are the number of roller rows and the inner/outer ring flanges as well as cage designs and materials.

The bearings can meet the challenges of applications faced with heavy radial loads and high speeds. Accommodating axial displacement (except for bearings with flanges on both the inner and outer rings), they offer high stiffness, low friction and long service life.

Cylindrical roller bearings are also available in sealed or split designs. In sealed bearings, the rollers are protected from contaminants, water and dust, while providing lubricant retention and contaminant exclusion. This provides lower friction and longer service life. Split bearings are intended primarily for bearing arrangements which are difficult to access, such as crank shafts, where they simplify maintenance and replacements.

Special variants

In addition to the bearings presented in this section, FV supplies cylindrical roller bearings for special application requirements. This assortment includes:

Features and benefits:

High load carrying capacity

High stiffness

Accommodate axial displacement

Low friction

Long service life

Enhanced operational reliability

Separable and interchangeable