Single row cylindrical roller bearings

| Principal dimensions [mm] | Basic load ratings [kN] | Speed ratings [r/min] | Designation | Design |

| dynamic | static | Reference speed | Limiting speed |

|

|

| d | D | B | C | C | C0 |

|

|

|

|

| 260 | 440 | 180 |

| 2200 | 3900 | 1300 | 1600 | NNU 4152 K30M/W33 | NNU K30/W33 |

| 260 | 440 | 180 |

| 2200 | 3900 | 1300 | 1600 | NNU 4152 M/W33 | NNU/W33 |

| 280 | 460 | 180 |

| 2550 | 4750 | 1200 | 1500 | NNU 4156 K30M/W33 | NNU K30/W33 |

| 280 | 460 | 180 |

| 2550 | 4750 | 1200 | 1500 | NNU 4156 M/W33 | NNU/W33 |

| 280 | 470 | 200 |

| 2700 | 5100 | 1000 | 1500 | 315976 B | NNU/C3W33 |

| 300 | 460 | 180 |

| 2600 | 5500 | 1000 | 1500 | BC2B 320119 |

|

| 300 | 500 | 200 |

| 2860 | 5300 | 1100 | 1400 | NNU 4160 K30M/W33 | NNU K30/W33 |

| 300 | 500 | 200 |

| 2860 | 5300 | 1100 | 1400 | NNU 4160 M/W33 | NNU/W33 |

| 320 | 440 | 118 |

| 1020 | 2360 | 1400 | 1500 | NNUP 4964 B/HB1W33 | NNUP/W33 |

| 320 | 460 | 120 |

| 1720 | 3600 | 950 | 1400 | BC2B 322216 |

|

| 320 | 480 | 175 |

| 2460 | 5400 | 950 | 1400 | 315583 C | NNU.4/C3W33 |

| 320 | 540 | 218 |

| 3410 | 6200 | 1000 | 1300 | NNU 4164 K30F | NNU K30 |

| 320 | 540 | 218 |

| 3690 | 6200 | 1000 | 1300 | NNU 4164 F |

|

| 340 | 520 | 305 | 200 | 3300 | 7100 | 900 | 1300 | BC2B 320118 | NNUB.2/C3WO |

| 340 | 580 | 243 |

| 4020 | 7500 | 950 | 1200 | NNU 4168 K30M/W33 | NNU K30/W33 |

| 340 | 580 | 243 |

| 4020 | 7500 | 950 | 1200 | NNU 4168 M/W33 | NNU/W33 |

| 350 | 520 | 150 |

| 2120 | 4500 | 850 | 1300 | BC2B 319878 | NNU/W33 |

| 360 | 500 | 125 |

| 1790 | 3650 | 900 | 1300 | BC2B 320075 | NNU/C3W33 |

| 360 | 500 | 125 |

| 2050 | 4300 | 900 | 1300 | BC2B 322217 |

|

| 360 | 600 | 243 |

| 4290 | 8500 | 900 | 1100 | NNU 4172 K30M |

|

| 370 | 520 | 220 | 193 | 2750 | 6700 | 850 | 1300 | BC2B 319961 | NNUB.1/W33WI |

| 380 | 480 | 100 |

| 952 | 2550 | 1200 | 1300 | NNU 4876 K/W33 | NNU K/W33 |

| 380 | 480 | 100 |

| 952 | 2550 | 1200 | 1300 | NNU 4876/HB1W33 | NNU/W33 |

| 380 | 540 | 130 |

| 2010 | 4300 | 800 | 1200 | BC2B 326131/HB1 |

|

| 380 | 540 | 200 |

| 2860 | 6800 | 800 | 1200 | BC2B 320041 | NNU.1/C4W33 |

| 380 | 620 | 243 |

| 4290 | 8500 | 850 | 1100 | NNU 4176 K30M |

|

| 380 | 620 | 243 |

| 4290 | 8500 | 850 | 1100 | NNU 4176 M |

|

| 400 | 500 | 100 |

| 968 | 2750 | 1100 | 1200 | NNU 4880/HB1W33 | NNU/W33 |

| 400 | 500 | 100 |

| 968 | 2750 | 1100 | 1200 | NNUP 4880/HB1W33 | NNUP/W33 |

| 400 | 500 | 100 |

| 968 | 2750 | 1200 | 1200 | NNU 4880 K/W33 | NNU K/W33 |

| 400 | 560 | 205 |

| 3140 | 7800 | 800 | 1200 | 314987 B | NNU.4/C4W33WI |

| 400 | 560 | 205 |

| 3140 | 7800 | 800 | 1200 | 314987 C | NNU.4/C4W33WI |

| 400 | 600.19 | 200 |

| 3470 | 7200 | 750 | 1100 | BC2B 326363/HA4 | NN.1/W33 |

| 400 | 650 | 250 |

| 4730 | 9500 | 800 | 1000 | NNU 4180 K30M/W33 | NNU K30/W33 |

| 400 | 650 | 250 |

| 4730 | 9500 | 800 | 1000 | NNU 4180 M/W33 | NNU/W33 |

| 410 | 600 | 220 |

| 3800 | 8650 | 750 | 1100 | 316019 | NNU.4/C4W33WI |

| 420 | 520 | 100 |

| 990 | 2850 | 1100 | 1200 | NNU 4884 K/W33 | NNU K/W33 |

| 420 | 520 | 100 |

| 990 | 2850 | 1100 | 1200 | NNU 4884/W33 | NNU/W33 |

| 420 | 580 | 130 |

| 2380 | 5300 | 750 | 1100 | BC2B 326137/HB1 |

|

| 420 | 580 | 160 |

| 2330 | 5400 | 750 | 1100 | 313555 A |

|

| 420 | 600 | 220 |

| 3580 | 8800 | 750 | 1100 | 314982 | NNU.2/C4W33 |

| 420 | 620 | 200 |

| 3470 | 7800 | 700 | 1100 | 314391 | NNU.3/C4W33WI |

| 440 | 540 | 100 |

| 1010 | 2900 | 1000 | 1100 | NNU 4888 KM/W33 | NNU K/W33 |

| 440 | 540 | 100 |

| 1170 | 3400 | 1000 | 1100 | NNU 4888 M/W33 | NNU/W33 |

| 440 | 620 | 225 |

| 3910 | 9800 | 700 | 1000 | 316077 A | NNU.4/C4W33WI |

| 440 | 640 | 230 |

| 4570 | 9800 | 850 | 1000 | BC2B 316521 | NNU.4/W33W |

| 440 | 720 | 280 |

| 5720 | 11800 | 700 | 900 | NNU 4188 K30M/W33 | NNU K30/W33 |

| 440 | 720 | 280 |

| 5720 | 11800 | 700 | 900 | NNU 4188 M/W33 | NNU/W33 |

| 457.2 | 660.4 | 228.6 | 203.2 | 3690 | 8150 | 670 | 950 | BC2B 322969/HB1 | NNUB/W33 |

| 460 | 580 | 118 |

| 1190 | 3250 | 1000 | 1100 | NNU 4892 K/W33 | NNU K/W33 |

| 460 | 580 | 118 |

| 1190 | 3250 | 1000 | 1100 | NNU 4892/W33 | NNU/W33 |

| 460 | 650 | 235 |

| 4400 | 11200 | 670 | 1000 | 316739 A | NNU.4/C4W33WI |

| 460 | 760 | 300 |

| 6440 | 12900 | 670 | 850 | NNU 4192 K30M | NNU K30 |

| 460 | 760 | 300 |

| 6440 | 12900 | 670 | 850 | NNU 4192 M |

|

| 460 | 780 | 280 |

| 5610 | 10400 | 560 | 850 | BC2-8004/HA1 |

|

| 480 | 700 | 260 |

| 5390 | 12500 | 600 | 900 | 316189 | NNU.3/C3W33 |

| 480 | 790 | 308 |

| 7040 | 14300 | 630 | 800 | NNU 4196 K30M/W33 | NNU K30/W33 |

| 480 | 790 | 308 |

| 7040 | 14300 | 630 | 800 | NNU 4196 M/W33 | NNU/W33 |

| 487.98 | 637 | 175 |

| 3000 | 7600 | 670 | 950 | BC2B 326196/HA1 | NN/C2W20WI |

| 490 | 694 | 174 |

| 3740 | 9000 | 600 | 900 | 316639 AG |

|

| 500 | 680 | 225 |

| 4130 | 11000 | 600 | 900 | 314990 A | NNU.4/C4W33WI |

| 500 | 720 | 218 |

| 4730 | 10800 | 600 | 850 | 314419 | NNU.3/C3W33WI |

| 500 | 830 | 325 |

| 7480 | 15000 | 600 | 800 | NNU 41/500 K30M/W33 | NNU K30/W33 |

| 500 | 830 | 325 |

| 7480 | 15000 | 600 | 800 | NNU 41/500 M/W33 | NNU/W33 |

| 530 | 780 | 225 |

| 4400 | 9500 | 530 | 800 | BC2B 326064/HA1 | NNU/W33 |

| 530 | 780 | 250 |

| 4680 | 10200 | 530 | 800 | 315040 A | NNU/W33W |

| 530 | 780 | 475 | 285 | 7210 | 17300 | 530 | 800 | BC2B 320117/HA4 | NNUB.3/C3WO |

| 530 | 870 | 335 |

| 7810 | 16000 | 560 | 750 | NNU 41/530 K30M/W33 | NNU K30/W33 |

| 530 | 870 | 335 |

| 7810 | 16000 | 560 | 750 | NNU 41/530 M/W33 | NNU/W33 |

| 550 | 800 | 260 |

| 5830 | 13400 | 530 | 750 | 316115 | NNU.3/C3W33 |

| 560 | 920 | 355 |

| 8800 | 18300 | 530 | 670 | NNU 41/560 K30M/W33X | NNU K30/W33 |

| 560 | 920 | 355 |

| 8800 | 18300 | 530 | 670 | NNU 41/560 M/W33 | NNU/W33 |

| 600 | 820 | 287.5 |

| 6440 | 18000 | 480 | 700 | BC2B 319584/HA1 | NNU.4/C4W33WI |

| 600 | 820 | 365 |

| 7810 | 21200 | 480 | 700 | BC2-8005/HB1 | NNU/CNW33 |

| 600 | 980 | 375 |

| 9900 | 21200 | 480 | 630 | NNU 41/600 K30M/W33 | NNU K30/W33 |

| 600 | 980 | 375 |

| 9900 | 21200 | 480 | 630 | NNU 41/600 M/W33 | NNU/W33 |

| 630 | 850 | 218 |

| 4400 | 11800 | 480 | 700 | BC2-8012/HB1 | NNU.7/C4WO |

| 630 | 1030 | 400 |

| 11000 | 24000 | 450 | 600 | NNU 41/630 K30M/W33 | NNU K30/W33 |

| 630 | 1030 | 400 |

| 11000 | 24000 | 450 | 600 | NNU 41/630 M/W33 | NNU/W33 |

| 650 | 920 | 335 |

| 8580 | 23200 | 530 | 630 | BC2B 326894/HB1 | NNU.4/C4W33WI |

| 660 | 880 | 225 |

| 4180 | 11800 | 450 | 670 | 313477 B |

|

| 670 | 1090 | 412 |

| 12100 | 25500 | 430 | 530 | NNU 41/670 K30M/W33 | NNU K30/W33 |

| 670 | 1090 | 412 |

| 12100 | 25500 | 430 | 530 | NNU 41/670 M/W33 | NNU/W33 |

| 690 | 980 | 365 |

| 10500 | 27000 | 400 | 600 | BC2-8074/HA5 | NNU.3/CNW33 |

| 690 | 980 | 550 | 357.5 | 9900 | 27000 | 400 | 600 | BC2-8015/HB1 | NNUB.5/W33WI |

| 710 | 1150 | 438 |

| 13400 | 28500 | 380 | 500 | NNU 41/710 K30M/W33 | NNU K30/W33 |

| 710 | 1150 | 438 |

| 13400 | 28500 | 380 | 500 | NNU 41/710 M/W33 | NNU/W33 |

| 750 | 1000 | 250 |

| 6160 | 16600 | 380 | 560 | 314420 | NNU.3/C4W33WI |

| 750 | 1220 | 475 |

| 16100 | 35500 | 380 | 450 | NNU 41/750 K30M/W33 | NNU K30/W33 |

| 750 | 1220 | 475 |

| 16800 | 36500 | 360 | 450 | NNU 41/750 M/W33 | NNU/W33 |

| 800 | 1260 | 375 |

| 12800 | 28000 | 300 | 430 | BC2B 326379/HA4 | NN.1/C2W33 |

| 800 | 1280 | 475 |

| 16500 | 36500 | 320 | 430 | NNU 41/800 K30M/W33 | NNU K30/W33 |

| 800 | 1280 | 475 |

| 17600 | 40500 | 340 | 430 | NNU 41/800 M/W33 | NNU/W33 |

| 850 | 1360 | 500 |

| 19800 | 45000 | 300 | 400 | NNU 41/850 K30M/W33 | NNU K30/W33 |

| 850 | 1360 | 500 |

| 19800 | 45000 | 300 | 400 | NNU 41/850 M/W33 | NNU/W33 |

| 900 | 1420 | 515 |

| 22000 | 47500 | 280 | 360 | NNU 41/900 K30M/W33 | NNU K30/W33 |

| 900 | 1420 | 515 |

| 22000 | 47500 | 280 | 360 | NNU 41/900 M/W33 | NNU/W33 |

| 950 | 1360 | 420 |

| 14000 | 33500 | 260 | 360 | BC2-8022/HA1 | NN/W33 |

| 950 | 1500 | 545 |

| 25500 | 57000 | 260 | 340 | NNU 41/950 K30M/W33 | NNU K30/W33 |

| 950 | 1500 | 545 |

| 25500 | 57000 | 260 | 340 | NNU 41/950 M/W33 | NNU/W33 |

| 1000 | 1580 | 580 |

| 27500 | 62000 | 240 | 300 | NNU 41/1000 K30M/W33 | NNU K30/W33 |

| 1000 | 1580 | 580 |

| 27500 | 62000 | 240 | 300 | NNU 41/1000 M/W33 | NNU/W33 |

| 1060 | 1660 | 600 |

| 30300 | 69500 | 220 | 280 | NNU 41/1060 K30M/W33 | NNU K30/W33 |

| 1060 | 1660 | 600 |

| 30300 | 69500 | 220 | 280 | NNU 41/1060 M/W33 | NNU/W33 |

| 1120 | 1750 | 630 |

| 33600 | 76500 | 200 | 280 | NNU 41/1120 K30M/W33 | NNU K30/W33 |

| 1120 | 1750 | 630 |

| 33600 | 76500 | 200 | 280 | NNU 41/1120 M/W33 | NNU/W33 |

| 1180 | 1850 | 670 |

| 36900 | 85000 | 180 | 240 | NNU 41/1180 K30M/W33 | NNU K30/W33 |

| 1180 | 1850 | 670 |

| 36900 | 85000 | 180 | 240 | NNU 41/1180 M/W33 | NNU/W33 |

| 1250 | 1950 | 710 |

| 41800 | 98000 | 160 | 220 | NNU 41/1250 K30M/W33 | NNU K30/W33 |

| 1250 | 1950 | 710 |

| 41800 | 98000 | 160 | 220 | NNU 41/1250 M/W33 | NNU/W33 |

| 1319.5 | 1720 | 300 |

| 12500 | 34500 | 160 | 240 | BC2B 326372/HA1 | NN.1/C4W33 |

| 1320 | 2060 | 750 |

| 45700 | 106000 | 150 | 190 | NNU 41/1320 K30M/W33 | NNU K30/W33 |

| 1320 | 2060 | 750 |

| 45700 | 106000 | 150 | 190 | NNU 41/1320 M/W33 | NNU/W33 |

| 1400 | 2180 | 775 |

| 49500 | 116000 | 130 | 170 | NNU 41/1400 K30M/W33 | NNU K30/W33 |

| 1400 | 2180 | 775 |

| 49500 | 116000 | 130 | 170 | NNU 41/1400 M/W33 | NNU/W33 |

| 1500 | 2300 | 800 |

| 52800 | 132000 | 120 | 150 | NNU 41/1500 K30M/W33 | NNU K30/W33 |

| 1500 | 2300 | 800 |

| 52800 | 132000 | 120 | 150 | NNU 41/1500 M/W33 | NNU/W33 |

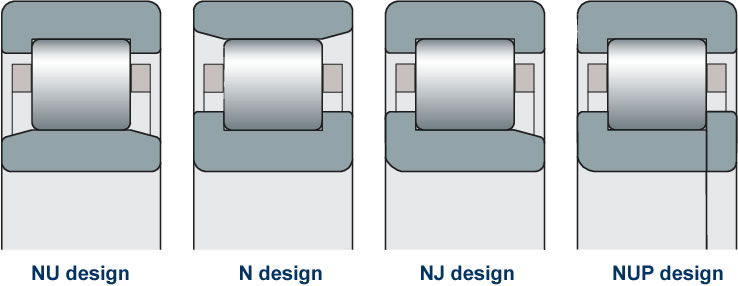

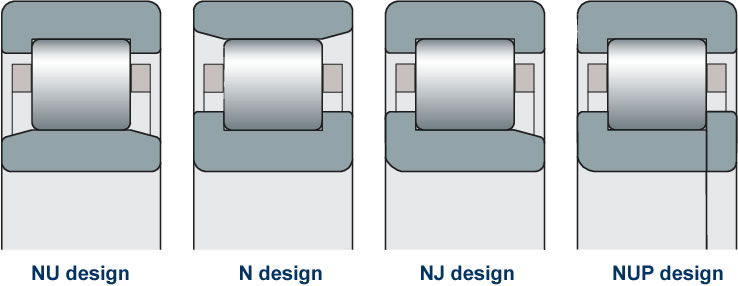

Cylindrical roller bearings are available in a wide range of designs, series, variants and sizes. The main design differences are the number of roller rows and the inner/outer ring flanges as well as cage designs and materials.

The bearings can meet the challenges of applications faced with heavy radial loads and high speeds. Accommodating axial displacement (except for bearings with flanges on both the inner and outer rings), they offer high stiffness, low friction and long service life.

Cylindrical roller bearings are also available in sealed or split designs. In sealed bearings, the rollers are protected from contaminants, water and dust, while providing lubricant retention and contaminant exclusion. This provides lower friction and longer service life. Split bearings are intended primarily for bearing arrangements which are difficult to access, such as crank shafts, where they simplify maintenance and replacements.

Special variants

In addition to the bearings presented in this section, FV supplies cylindrical roller bearings for special application requirements. This assortment includes:

Features and benefits:

High load carrying capacity

High stiffness

Accommodate axial displacement

Low friction

Long service life

Enhanced operational reliability

Separable and interchangeable

Cylindrical roller bearings are available in a wide range of designs, series, variants and sizes. The main design differences are the number of roller rows and the inner/outer ring flanges as well as cage designs and materials.

The bearings can meet the challenges of applications faced with heavy radial loads and high speeds. Accommodating axial displacement (except for bearings with flanges on both the inner and outer rings), they offer high stiffness, low friction and long service life.

Cylindrical roller bearings are also available in sealed or split designs. In sealed bearings, the rollers are protected from contaminants, water and dust, while providing lubricant retention and contaminant exclusion. This provides lower friction and longer service life. Split bearings are intended primarily for bearing arrangements which are difficult to access, such as crank shafts, where they simplify maintenance and replacements.

Special variants

In addition to the bearings presented in this section, FV supplies cylindrical roller bearings for special application requirements. This assortment includes:

Features and benefits:

High load carrying capacity

High stiffness

Accommodate axial displacement

Low friction

Long service life

Enhanced operational reliability

Separable and interchangeable

Cylindrical roller bearings are available in a wide range of designs, series, variants and sizes. The main design differences are the number of roller rows and the inner/outer ring flanges as well as cage designs and materials.

The bearings can meet the challenges of applications faced with heavy radial loads and high speeds. Accommodating axial displacement (except for bearings with flanges on both the inner and outer rings), they offer high stiffness, low friction and long service life.

Cylindrical roller bearings are also available in sealed or split designs. In sealed bearings, the rollers are protected from contaminants, water and dust, while providing lubricant retention and contaminant exclusion. This provides lower friction and longer service life. Split bearings are intended primarily for bearing arrangements which are difficult to access, such as crank shafts, where they simplify maintenance and replacements.

Special variants

In addition to the bearings presented in this section, FV supplies cylindrical roller bearings for special application requirements. This assortment includes:

Features and benefits:

High load carrying capacity

High stiffness

Accommodate axial displacement

Low friction

Long service life

Enhanced operational reliability

Separable and interchangeable