HSC bearing units with half-round outer ring for continuous casting machines

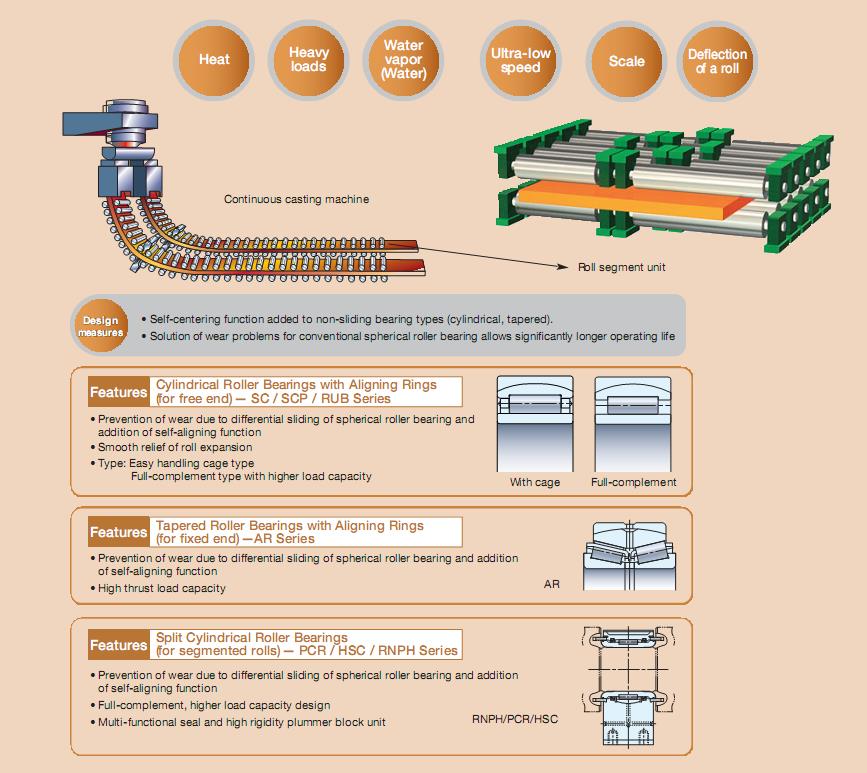

•In continuous casting machines, roll support bearings are used under heavy loads and at extremely low speed. In addition, the operating conditions are severe, resulting in exposure to splashing water and scales.

•SCP bearings for fixed side and SC bearings for free side are used for end of rolls.

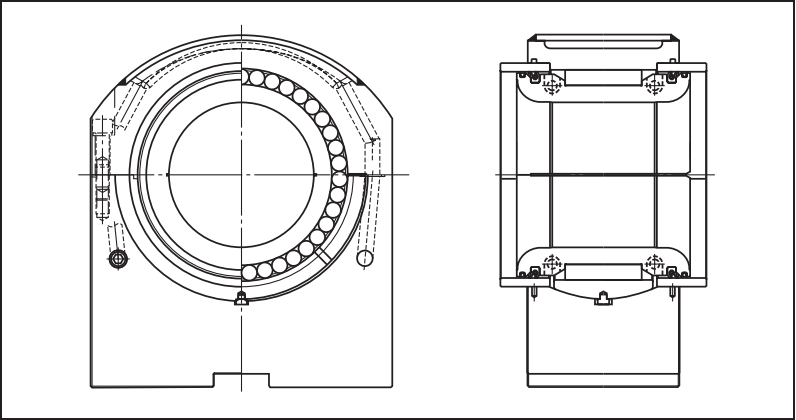

•HSC bearing units with half-round outer ring is used for the intermediate support section of beetle-shape rolls, such as driving rolls.

•FV bearings for continuous casting machines are designed based on a full complement cylindrical roller bearing, with reference to maximized static load ratings. Crowning are set up on rolling surface of its rollers, according to the size of loads, which contributes to solve stress concentration at specific location.

•The bearing has the self-aligning mechanism to absorb roll bending and misalignment due to heavy load.

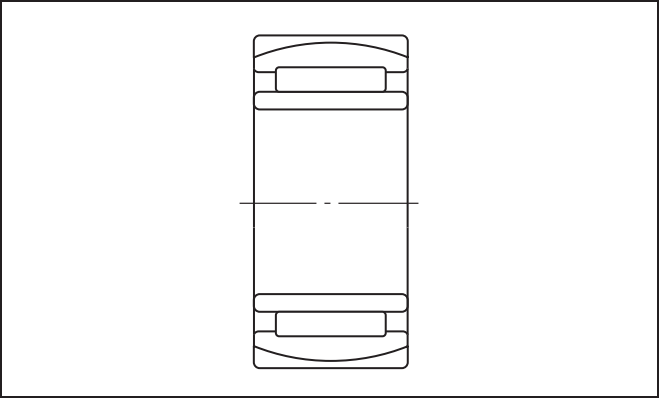

SC bearings (free side)

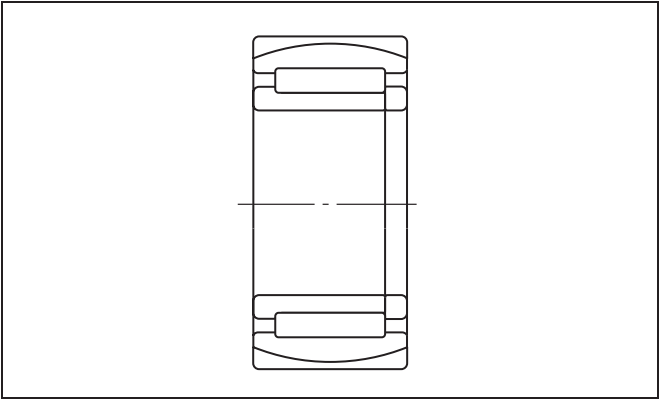

| SCP bearings (fixed side)

|

• To accommodate thermal contraction andexpansion of roll, the inner ring of this bearingare designed to move smoothly in the axial direction. | • The bearing has been developed for the purpose of improvement in short service life of spherical roller bearings most commonly used for continuous casting machines. • The ribs provided for the inner and outer rings and loose rib allow accommodation of axial loads generated by thermal contraction and expansion of rolls. |

HSC bearing units with half-round outer ring

| • To accommodate thermal contraction and expansion of roll, the inner ring and roller of this bearing are designed to move smoothly in the axial direction. • This unit has unique structure, with a half-round outer ring placed on the loaded side only. • This special half-round outer ring and compact seal design realizes a 15 % increase in static load rating over that of conventional products. • The unique jacket design adjusts the flow of water and enables a high cooling efficiency, equivalent to that of conventional products with a lower water flow rate of 55 %. |

HSC bearing units with half-round outer ring for continuous casting machines

| Housing unit | Roll outside | Boundary dimensions (mm) | Seal type | Bearing No. | Acceptable | Basic load | |||||||

| dia. (mm) | Recovery | Non-recovery | roll heat | ratings (kN) | |||||||||

| No. | D | d | B | H | Di | D2 | r | type | type | expansion (mm) | C | Co | |

| PBA391H | 195 | 100 | 145 | 175 | 133 | 143 | C8 | — | O | HSC2017-1C3 | ±7 | 373 | 876 |

| PBA399H | 220 | 110 | 139 | 225 | 155 | 168 | 18 | O | — | HSC2219-7C3 | ±9 | 402 | 876 |

| PBA360H | 220 | 110 | 139 | 225 | 155 | 168 | 18 | O | — | HSC2219-6C3 | ±9 | 433 | 966 |

| PBA328H | 225 | 100 | 169 | 132 | 140 | 150 | 15 | — | O | HSC2019C3 | ±8 | 603 | 1250 |

| PBA171H | 230 | 110 | 113 | 185 | 160 | 173 | 13 | — | O | HSC2219-3C3 | ±8 | 337 | 619 |

| PBA171H | 230 | 110 | 113 | 185 | 160 | 173 | 13 | O | — | HSC2219-8C3 | ±8 | 337 | 619 |

| PBA171AXH | 230 | 110 | 141 | 246 | 160 | 173 | 18 | — | O | HSC2219-1C3 | ±8 | 528 | 1120 |

| PBA171AH | 230 | 110 | 148 | 351 | 160 | 173 | 13 | — | O | HSC2219C3 | ±8 | 421 | 846 |

| PBA171AH | 230 | 110 | 148 | 351 | 160 | 173 | 13 | O | — | HSC2219-9C3 | ±8 | 421 | 846 |

| PBA208H | 230 | 110 | 150 | 190 | 160 | 173 | 15 | — | O | HSC2219-2C3 | ±8 | 554 | 1190 |

| PBA208H | 230 | 110 | 150 | 190 | 160 | 173 | 15 | O | — | HSC2219-11C3 | ±8 | 554 | 1190 |

| PBA368H | 230 | 110 | 154 | 180 | 160 | 173 | 20 | — | O | HSC2219-4C3 | ±8 | 554 | 1190 |

| PBA404H | 230 | 110 | 154 | 180 | 160 | 173 | 20 | O | — | HSC2220C3 | ±9 | 575 | 1270 |

| PBA339H | 235 | 140 | 145 | 175 | 175 | 186.5 | C8 | — | O | HSC2821C3 | ±5 | 431 | 1160 |

| PBA316H | 240 | 115 | 202 | 251 | 160 | 175 | 15 | — | O | HSC2321C3 | ±10 | 745 | 1550 |

| PBA316H | 240 | 115 | 202 | 251 | 160 | 175 | 15 | O | — | HSC2321-2C3 | ±10 | 745 | 1550 |

| PBA396H | 240 | 120 | 173 | 230 | 165 | 180 | 15 | O | — | HSC2421-2C3 | ±9 | 673 | 1510 |

| PBA411H | 250 | 120 | 151 | 190 | 172 | 185 | 20 | O | — | HSC2421-6C3 | ±9 | 576 | 1310 |

| PBA336H | 250 | 120 | 153 | 185 | 175 | 190 | 20 | — | O | HSC2421C3 | ±8 | 651 | 1380 |

| PBA336AH | 250 | 120 | 153 | 145 | 175 | 190 | 20 | — | O | HSC2421C3 | ±8 | 651 | 1380 |

| PBA378H | 250 | 120 | 154 | 175 | 170 | 188 | 20 | O | — | HSC2421-1C3 | ±10 | 578 | 1190 |

| PBA251H-2 | 250 | 120 | 154 | 190 | 175 | 190 | 20 | O | — | HSC2421-4C3 | ±9 | 605 | 1400 |

| PBA251H | 250 | 120 | 154 | 180 | 175 | 190 | 20 | — | O | HSC2421-3C3 | ±9 | 605 | 1400 |

| PBA407H | 250 | 120 | 154 | 180 | 170 | 185 | 20 | O | — | HSC2421-5C3 | ±9 | 605 | 1400 |

| PBA410H | 255 | 125 | 174 | 180 | 180 | 195 | 20 | O | — | HSC2522C3 | ±9 | 793 | 1740 |

| PBA379H | 260 | 120 | 154 | 180 | 170 | 188 | 20 | O | — | HSC2421-1C3 | ±10 | 578 | 1190 |