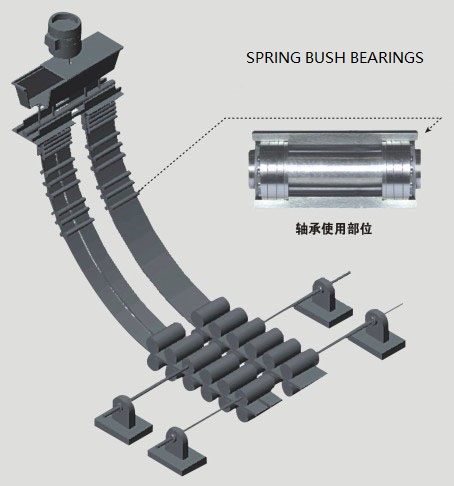

Spring Bush Bearing for Continuous Casting Mill

There are several types of bearing that can be used for CCM (continuous casting mill), like Spherical roller bearing, Carb bearing and cylindrical roller bearing.

In addition, there is a special kind of bearing that can be used also -- Spring bush bearing.

1)The spring bush bearing made of spring steel, its Annealing temperature is 3500℃, so those kinds of suitable for high temperature working.

2)The spring steel has good resilience, and easier to assemble.

3)This kind of bearing is durable and not greatly affected by the weak acid formed by dirt, iron filings, water, and fallen iron powder and water.

4)The main advantage of sping bearings is that the outer ring can be reused many times, which makes it possible to rework it once it is damaged or bent due to temperature.

High temperature - thermal radiation temperature in casting blank

Shock - shock vibration load incurred in jiggering blank

Dust - metal oxide producing in cooling cast blank

Waste water - flow and high-temperature steam of cooling water

| Bearing No. | Boundary Dimensions(mm) | Load ratings(KN) | Limiting Speeds(r/min) | Mass(Kg) | ||||||

| New | old | d | D | B | C | Cr | Cor | Grease | Oil | |

| CS8105 | - | 25 | 46 | 40 | - | 60 | 80 | - | - | 0.3 |

| CS8106 | - | 30 | 55 | 44 | - | 71 | 84 | - | - | 0.452 |

| AS8106W | - | 30 | 62 | 36 | 50 | 71 | 84 | - | - | 0.4 |

| AS8107WH | - | 35 | 60 | 37 | 63 | 83 | 125 | - | - | 0.64 |

| AS8107WN | - | 35 | 62 | 36 | 50 | 97 | 145 | - | - | 0.662 |

| AS8107W | - | 35 | 65 | 38 | 64 | 104 | 165 | - | - | 0.98 |

| AS8107N | - | 35 | 65 | 38 | 56.5 | 104 | 165 | - | - | 0.877 |

| AS8107W1 | - | 35 | 60 | 38 | 64 | 83 | 125 | - | - | 0.63 |

| AS8108 | NB4608Y | 40 | 71 | 32 | 32 | 70 | 91 | - | - | 1 |

| AS8108W | - | 40 | 71 | 45 | 60 | 95 | 136 | - | - | 0.93 |

| AS8108WH | - | 40 | 71 | 43.5 | 58 | 94.6 | 135.7 | - | - | 0.93 |

| AS8208 | 115908X1 | 40 | 71 | 30 | 40 | 70 | 91 | - | - | 0.84 |

| AS8208E | - | 40 | 71 | 28 | 40 | 70 | 91 | - | - | 0.88 |

| AS9108 | 115908X2 | 40 | 78 | 45 | 57 | 100 | 136 | - | - | 1.04 |

| AS9108WN | - | 40 | 77 | 45 | 57 | 70 | 91 | - | - | 1.33 |

| AS9208 | - | 40 | 82 | 62 | 80 | 180 | 216 | - | - | 1.51 |

| AS9208X | - | 40 | 82 | 50 | 59 | 80 | 110 | - | - | 1.44 |

| AS9208E | - | 40 | 82 | 62 | 80 | 85 | 110 | - | - | 1.51 |

| AS8108X | - | 40 | 71 | 47 | 57 | 100 | 136 | - | - | *1.310 |

| AS8108X1 | - | 40 | 66 | 45 | 58 | 72 | 100 | - | - | 0.68 |

| AS7109 | - | 45 | 70 | 63 | 73 | 110 | 200 | - | - | 1.125 |

| AS8109 | 115909X | 45 | 80 | 55 | 65 | 138 | 213 | - | - | 1.51 |

| AS8109W | - | 45 | 80 | 63 | 73 | 138 | 213 | - | - | 1.65 |

| AS8109WE | - | 45 | 80 | 81 | 90 | 211 | 252 | - | - | *2.140 |

| AS8209 | - | 45 | 80 | 70 | 70 | 138 | 213 | - | - | 1.53 |

| AS9109 | - | 45 | 80 | 60 | 64 | 138 | 213 | - | - | 1.3 |

| AS7210W | - | 50 | 72 | 63 | 73 | 140 | 225 | - | - | 1.25 |

| AS8210 | 105910 | 50 | 95 | 70 | 95 | 230 | 272 | - | - | 2.31 |

| AS9110 | 115910 | 50 | 95 | 63 | 90 | 138 | 213 | - | - | 1.61 |

| AS8210W | - | 50 | 85 | 45 | 73 | 55 | 125 | - | - | 1.53 |

| AS8210WN | - | 50 | 85 | 70 | 80 | 220 | 267 | - | - | 2.02 |

| AS8111W | - | 55 | 90 | 63 | 73 | 138 | 213 | - | - | 2.07 |

| AS8211W | - | 55 | 95 | 63 | 73 | 138 | 213 | - | - | 2.15 |

| AS8111 | - | 55 | 90 | 81 | 100 | 206 | 336 | - | - | *1.870 |

| AS8211WN | - | 55 | 90 | 72 | 90 | 220 | 310 | - | - | 2.376 |

| AS8112W | - | 60 | 95 | 63 | 73 | 206 | 336 | - | - | 2.18 |

| AS8112W2 | - | 60 | 95 | 60.3 | 76 | 184 | 360 | - | - | 1.76 |

| AS7212WB | - | 60 | 95 | 60.3 | 76 | 184 | 360 | - | - | 2.34 |

| AS8212W | - | 60 | 105 | 63 | 73 | 236 | 366 | - | - | 2.77 |

| AS8312 | - | 60 | 90 | 55 | 65 | 206 | 336 | - | - | *1.170 |

| AS8212IC | - | 60 | 100 | 63 | 90 | 236 | 366 | - | - | 2.85 |

| AS8212NL | - | 60 | 100 | 62 | 67 | 206 | 336 | - | - | 2.2 |

| AS9112 | - | 60 | 110 | 80 | 105 | 236 | 366 | - | - | 3.35 |

| AS9212 | - | 60 | 110 | 94 | 105 | 210 | 350 | - | - | 3.3 |

| AS8212WN | - | 60 | 89 | 63 | 73 | 138 | 213 | - | - | 1.63 |

| AS8112WB | - | 60 | 95 | 63 | 73 | 138 | 213 | - | - | 2.48 |

| AS8312NL | - | 60 | 90 | 68 | 73 | - | - | - | - | 1.895 |

| AS81/62W | - | 62 | 89 | 63 | 73 | 184 | 360 | - | - | 1.608 |

| AS8113NL | - | 65 | 100 | 72 | 90 | 190 | 330 | - | - | 2.664 |

| AS8113W | - | 65 | 110 | 63 | 73 | 206 | 336 | - | - | 3.18 |

| AS8113 | - | 65 | 110 | 81 | 120 | 170 | 365 | - | - | 4.31 |

| AS7214W | - | 70 | 100 | 63 | 73 | 190 | 300 | - | - | 1.87 |

| AS7214W1 | - | 70 | 99 | 63 | 73 | 159 | 335 | - | - | 1.71 |

| AS8114 | - | 70 | 115 | 65 | 87 | 133 | 213 | - | - | 3.014 |

| AS8214 | - | 70 | 120 | 80 | 80 | 360 | 474 | - | - | 3.66 |

| AS8214W | - | 70 | 120 | 63 | 73 | 246 | 389 | - | - | 3.536 |

| AS8215M | - | 75 | 105 | 54 | 60 | 235 | 425 | - | - | *1.420 |

| AS8115 | - | 75 | 115 | 80 | 90 | 235 | 425 | - | - | 3.05 |

| AS8115W | - | 75 | 105 | 63 | 73 | 170 | 365 | - | - | 2.012 |

| AS8115WI | - | 75 | 115 | 72 | 90 | 235 | 425 | - | - | 3.52 |

| AS8115WB | - | 75 | 116 | 47 | 55 | 169 | 288 | - | - | 2.74 |

| AS8215Y | - | 75 | 105 | 54 | 54 | 190 | 300 | - | - | 1.49 |

| AS8115NL | - | 75 | 120 | 72 | 90 | 260 | 395 | - | - | 3.915 |

| AS8116W | - | 80 | 120 | 63 | 73 | 773 | 808 | - | - | 3.13 |

| AS8116NL | - | 80 | 125 | 65 | 70 | - | - | - | - | 3.37 |

| AS8117W | - | 85 | 120 | 63 | 73 | 215 | 451 | - | - | 3.05 |

| AS8118W | - | 90 | 125 | 62 | 70 | 235 | 425 | - | - | 3.05 |

| AS8218W | - | 90 | 121 | 63 | 73 | 250 | 538 | - | - | 2.36 |

| AS8218W1 | - | 90 | 130 | 63 | 73 | 255 | 488 | - | - | 3.195 |

| AS8119NL | - | 95 | 130 | 65 | 70 | - | - | - | - | 3.363 |

| S8628 | - | 140 | 180 | 100 | - | - | - | - | - | 7.87 |

| DS5218W | - | 90 | 153 | 112 | 140 | - | - | - | - | 10.32 |

| DS8218W | - | 90 | 153 | 56×2 | 140 | - | - | - | - | 10.32 |

| DS5220W | - | 100 | 165 | 64 | 84 | - | - | - | - | 8.05 |

| DS8220W | - | 100 | 165 | 64 | 90 | - | - | - | - | 8.05 |